BEFORE. DURING, AFTER.

SMEG IS A RELIABLE PARTNER AT EVERY WORK STAGE.

MOULD CONSTRUCTION

Stability and durability over time. The moulds we make, single or multi-cavity, up to a maximum size of 800×500, are made with certified hardening steels and heat treatments.

This ensures the customer a satisfactory and reliable result.

With the company’s equipment we can guarantee a minimum of 1,000,000 impressions accompanied by a technical moulding test.

MOULD PROTOTYPING

We can design and produce prototypes with maximum customization. Our prototypes are perfect for use at the start of production, before the final mould is made. Our prototypes ensure in detail final product performance and mass production features.

Prototypes can be created with unhardened moulds, and we can also provide resistance and ageing test phases to optimise production and avoid errors.

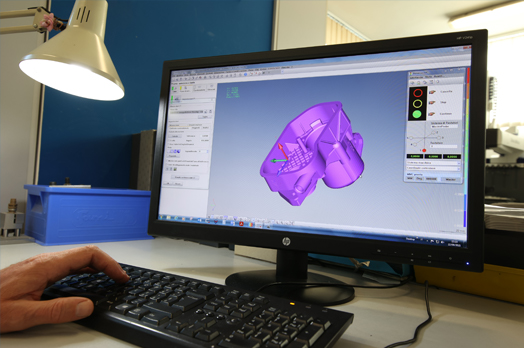

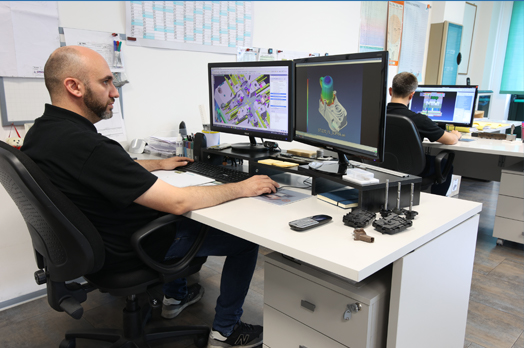

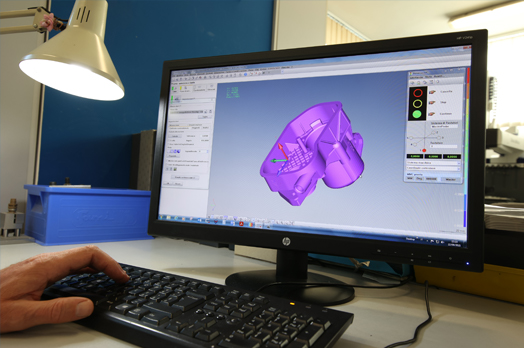

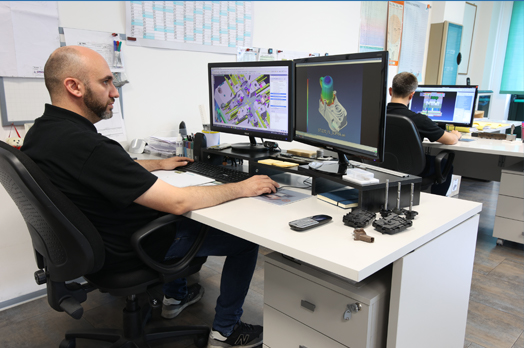

MOULD DESIGN

We use the most important CAD design programmes to ensure that our prototypes adequately meet the need for which they were designed, making them compatible with injection moulding technologies.

At the design stage, we make sure that the prototype is of the highest quality: that’s why we carry out metrological tests and Mould Flow analysis, which highlight any issues that can be resolved before the actual tooling is built.

MOULD MAINTENANCE

We also support our customers once the moulds have been installed with scheduled maintenance or timely assistance in the event of a malfunction.

We also work on machinery manufactured by other companies, upon request we can carry out laser cladding on steel with hardness varying from 45 to 60 HRC and we offer a rapid on-site maintenance service for polishing or small repairs on mounted equipment.

MOULD CONSTRUCTION

Stability and durability over time. The moulds we make, single or multi-cavity, up to a maximum size of 800×500, are made with certified hardening steels and heat treatments.

This ensures the customer a satisfactory and reliable result.

With the company’s equipment we can guarantee a minimum of 1,000,000 impressions accompanied by a technical moulding test.

MOULD PROTOTYPING

We can design and produce prototypes with maximum customization. Our prototypes are perfect for use at the start of production, before the final mould is made. Our prototypes ensure in detail final product performance and mass production features.

Prototypes can be created with unhardened moulds, and we can also provide resistance and ageing test phases to optimise production and avoid errors.

MOULD DESIGN

We use the most important CAD design programmes to ensure that our prototypes adequately meet the need for which they were designed, making them compatible with injection moulding technologies.

At the design stage, we make sure that the prototype is of the highest quality: that’s why we carry out metrological tests and Mould Flow analysis, which highlight any issues that can be resolved before the actual tooling is built.

MOULD MAINTENANCE

We also support our customers once the moulds have been installed with scheduled maintenance or timely assistance in the event of a malfunction.

We also work on machinery manufactured by other companies, upon request we can carry out laser cladding on steel with hardness varying from 45 to 60 HRC and we offer a rapid on-site maintenance service for polishing or small repairs on mounted equipment.